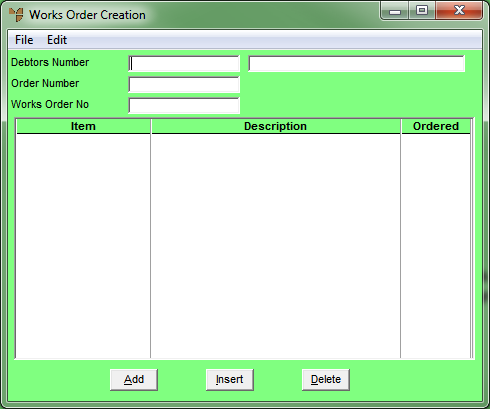

You use the Works Order Creation screen to create a new works order for a manufactured kit item, or to load a works order you have previously saved. The works order may have been created manually using the procedures in this section, or automatically via the Trial Kitting or Auto Kitting programs.

To create and maintain works orders, you need to complete these steps:

Refer to "Maintaining the Works Order Creation Header".

Refer to "Entering Works Order Lines".

Refer to "Works Order Creation - Edit Menu Options".

Refer to "Works Order Creation - File - Print".

When the works order item(s) have been assembled:

Refer to "Works Order Creation - Edit - Complete All".

Refer to "Works Order Creation - File - Post Completed Stock".